However, since the production process takes three weeks to complete, all the units produced in the last half of March will be in WIP inventory at the end of March. Figure 3.8 “Flow of Costs through the Work-in-Process Inventory T-Account of Desk Products’ Assembly Department” shows the flow of costs through the work-in-process inventory T-account for the Assembly department. Recall that Desk Products, Inc., has two departments—Assembly and Finishing. Although this chapter focuses on the Assembly department, the Finishing department would also use the four steps to determine product costs for completed units transferred out and ending WIP inventory. Table 3.2 “Production Information for Desk Products’ Assembly Department” presents information for the Assembly department at Desk Products for the month of May.

Data Analytics

- The food industry uses process costing to calculate the cost of producing food products.

- Coca-cola is a carbonated drink bottling company that specializes in unique flavors.

- The costs added in each process during the current period is prorated to the production necessary to complete the opening work in progress, to complete the units added in the process and units in the work in progress.

- Rock City Percussion uses a process cost system because the drumsticks are produced in batches, and it is not economically feasible to trace the direct labor or direct material, like hickory, to a specific drumstick.

Process costing is optimal when the costs cannot be traced directly to the job. For example, it would be impossible for David and William to trace the exact amount of eggs in each chocolate chip cookie. Even two sticks made sequentially may have different weights because the wood varies in density. Understanding the company’s organization is an important first step in any costing system.

Direct Materials

- Similar calculations are performed for the labeling and packing divisions, and the corporation discovers that it cost $100,000 to make 50,000 bottles in one month.

- This method is typically used when each unit can be identified and tracked separately, such as in custom manufacturing or high-value goods.

- Incorporated in 1892 and headquartered in Atlanta, the company is the largest beverage producer and distributor globally, with an expansive product portfolio offered in over 200 countries and territories worldwide.

- There are situations whereby companies manufacture a broad mix of products and find it difficult to accurately assign actual costs to each type of product; in such instances, using standard costs can be very useful.

- Process costing system considers work in progress — things that have entered but have not completed the production process — at the beginning and end of each period to precisely estimate the cost of creating each unit.

When she sends a bid to a potential client, her direct costs include materials and labor expenses. AAA must also assign overhead costs such as the costs related to running the office, insurance premiums, and building lease. First, they start from the Designing and Cutting department where shoes are designed to fit with the trending market, and fabric will be cut to fit with each design. In March 200X, the Design and Cutting department incur the cost of direct material USD 100,000, direct labor cost of USD 150,000 and USD 80,000 of overhead cost. During month, this department has finished 10,000 pairs of shoes and passes them to next stage. Notice that two different work-in-process inventory accounts areused to track production costs—one for each department.

Direct labor

Job costing is less accurate since the actual prices may vary based on the specific requirements of each job. Due to its averaging approach, process costing does not easily allow for tracking changes between processes or products within the same department. It can make it difficult for management to understand what drives cost variances from period to period. The product’s final cost is determined by adding the costs incurred in each process and dividing it by the total number of units produced. It involves breaking down the entire process costing system inventory into individual elements, such as labor and materials costs, to identify discrepancies or overlaps.

- The production volume can also influence the selection of a process costing method.

- For this step, the number of incomplete units at the end of the period is multiplied by a percentage that represents their progress in the production process.

- Notice that the basic data are at the top of the spreadsheet, and the rest of the report is driven by formulas.

- This approach simplifies cost tracking by treating all units as identical, allowing businesses to determine the cost per unit by dividing total process costs by the number of units completed.

- Though it’s not a perfect allocation, it’s an accepted approach many companies use.

3 Determining Equivalent Units

In March 202X, this department has incurred a cost of direct labor USD 50,000, overhead cost USD 30,000. As a result, they have completed 8,000 pairs of shoes and pass the next stage. The calculation for the equivalent units of the production is an estimate which is not fully accurate. The inaccuracy of the work in process may result in the misstatement of the financial reporting.

- The company does not need to invest in an expensive accounting system just for product costing.

- Before implementing a process costing system, developing a detailed plan outlining the objectives, processes, and resources required before implementing a process costing system is essential.

- The next step in a process cost system is to calculate the equivalent units in order to account for items that are unfinished at the end of each period.

- Job order costing is a cost accounting system that accumulates manufacturing costs separately for each job.

- The presumption is that the cost of each unit is the same as the cost of any other unit, hence tracking information at the individual unit level is unnecessary.

- Process costing is used when product output is of low value, identical or near-identical products are mass produced, and costs cannot be tracked to individual products.

- For example, in a job order cost system, each job is unique, which allows management to establish individual prices for individual projects.

The output of this phase serves as the raw materials or inputs of the subsequent stage of blending, with the process culminating in the third step of packaging, where inspection and labeling occur. Notably, this process is defined as producing large batches of homogenous products through a consistent and standardized process. The company utilizes several work-in-process inventory accounts to track product costs through each production Accounting Security department. Hershey likely uses a process costing system since it produces identical units of product in batches employing a consistent process.

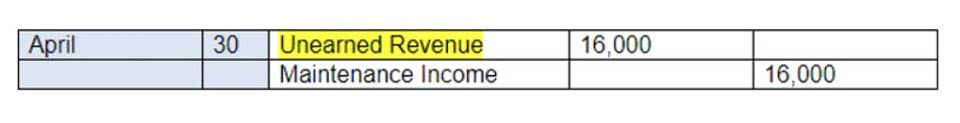

Preliminary figures show current year net income before taxes totaling $1,970,000, which is short of the target by $30,000. The president approaches you and asks you to increase the petty cash percentage of completion for the 40,000 units in ending WIP inventory to 90 percent for direct materials and to 95 percent for direct labor and overhead. Process costing is a method used by businesses to calculate the total production costs for a specific process or department within a company. It involves allocating costs to individual units of output based on the average cost incurred during the production process. Process costing is one of the important concepts in manufacturing accounting. If a process costing system does not work well with a company’s cost accounting systems, there are two more systems to consider.